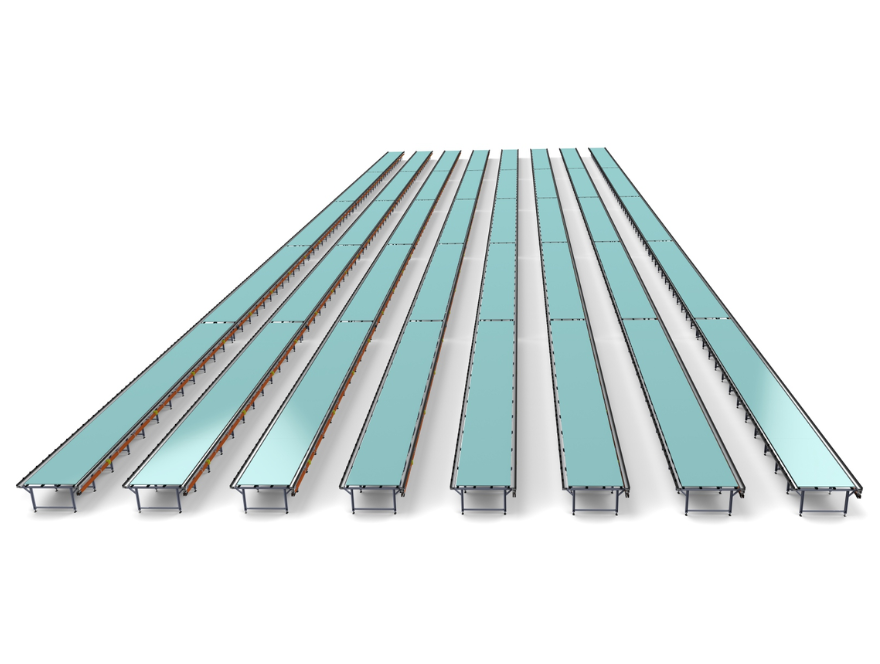

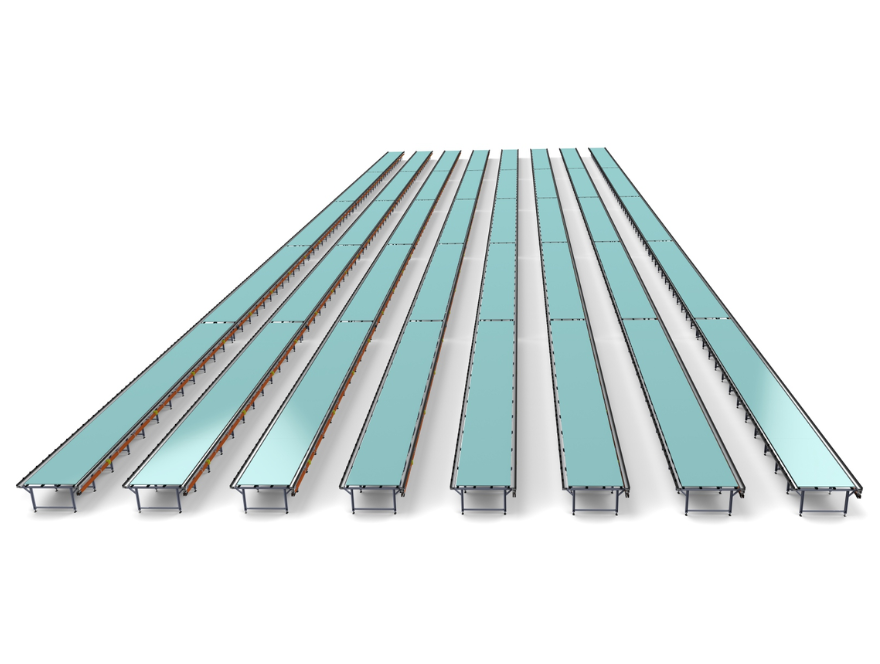

Our silk screen printing table is specially designed for the textile industry. It is widely used in clothing printing, ribbon printing, elastic band printing, luggage printing, shoe material printing, socks printing, transfer film printing, trademark printing, scarf printing, glove printing, elastic band printing, and other fields. It can meet the drying and printing needs of various semidry printing materials, such as silica gel, glue, ink, etc.

1. Customized size

Table width: It can be customized between 0.8 and 3.8 meters to adapt to textile printing jobs of different sizes. Whether it is a small studio or a large factory, you can find the right size to meet your production needs.

Table length: The range of 25 meters to 100 meters provides sufficient printing space to adapt to textile printing tasks of various lengths. Whether it is a long strip of ribbon or a large-format fabric, it can be easily handled.

2. Table selection

Ordinary glass table: It has high transparency, which is convenient for operators to observe the printing process and ensure printing accuracy. At the same time, the glass table is easy to clean, keeping the working environment clean; for textiles that require high precision printing, such as trademarks, transfer films, etc., ordinary glass table tops are ideal.

Table leather table top: Provides better wear resistance and antislip properties, suitable for handling heavier textiles or printing materials that need to be moved frequently. Table leather table tops also have a certain degree of elasticity, which can reduce vibration during printing and improve printing quality. Table leather table tops are more practical for textiles such as clothing, luggage, etc., that need to be frequently handled and operated.

No matter which tabletop you choose, we can customize it according to your specific requirements to meet your unique needs.

1. Matrix glue cup glass support

Table surface flatness is precisely adjustable: Through the matrix glue cup glass support system, our screen printing table can precisely adjust the table surface flatness. Within a range of 1.5 meters, the flatness is less than 0.3 mm. This high-precision design makes it particularly suitable for printing high-precision textiles. Whether it is a small pattern or a complex design, the clarity and accuracy of the printing can be guaranteed.

Durable table: The matrix glue cup glass support not only provides stable support but also has good durability. It can withstand long-term use and heavy-load printing tasks, ensuring the long service life of the table. It can maintain stable performance even in high-intensity production environments.

2. Adjustable foot cups and thickened brackets

The bracket has an adjustable foot cup height: Our screen printing table is equipped with an adjustable foot cup to adapt to uneven floors. You can easily adjust the height of the foot cup so that the table is always level and provides a stable foundation for printing work. This is essential to ensure printing quality and the regular operation of the equipment.

The bracket is made of thickened material: The bracket made of thickened material has higher strength and stability. The 950 mm spacing arrangement design further enhances the table's stability, ensuring that there will be no deformation or damage during long-term use. It can remain stable even when bearing heavier textiles and printing equipment.

3. Optimized table height and operating convenience

The table is 750 mm from the ground. This height has been carefully designed and is suitable for most people's operating habits. It makes the operator more comfortable and convenient when laying materials and performing other operations, improving work efficiency. At the same time, this height is also convenient for cooperation with different equipment to achieve automated production.

4. High-quality track design

Widened and thickened machine travel track: Our screen printing table adopts a widened and thickened machine travel track with small deformation and a durable track. This design ensures the machine is stable and reliable during walking, reduces vibration and deviation, and improves printing accuracy. Whether it is high-speed printing or long-term continuous operation, it can maintain stable performance.

Double-sided embedded stainless steel belt of aluminum profile track: The track is made of aluminum profile, and the double-sided embedded stainless steel belt is wear-resistant and scratch-resistant and can improve the limit positioning accuracy. This makes the machine walk more stable and accurate, ensuring stable printed product quality and a high qualification rate. This design is essential for textiles that require high-precision printing, such as trademarks, transfer films, etc.

5. Multifunction positioning code

Compatible with both machine and manual screen printing: Our screen printing platen is equipped with a multifunctional positioning code, which is suitable for both table screen printing machine operation and manual screen printing positioning. This design allows you to easily achieve accurate positioning in different production scenarios, improving printing efficiency and quality. Whether it is large-scale automated production or small-batch manual customization, it can meet your needs.

One investment for two uses: Choose our screen printing table, you only need to invest once to meet the needs of machine printing and manual printing at the same time. This saves money, labor, and time and provides more flexibility for your production. You can flexibly choose the production method according to the size and requirements of the order to improve production efficiency.

6. Safe and reliable power supply system

National standard busbar power supply: Our screen printing table adopts a national standard busbar power supply, which is safe, reliable, and durable. Printing machines and dryers can be connected to the point to facilitate your production layout and equipment connection. This power supply method not only provides a stable power supply but also reduces the problem of cluttered wires and improves the safety of the working environment.

1. High precision printing

The flatness of the table is precisely adjustable and suitable for machine printing high-precision textiles. Whether it is small text or complex patterns, the clarity and accuracy of printing can be guaranteed. This is essential to improve the quality and added value of products.

The track design is optimized, and the machine travels stably and with high precision. This makes the quality of printed products stable, the qualified rate is high, and the scrap rate and rework cost are reduced. This is an essential advantage for textile companies pursuing high quality.

2. Strong durability

The matrix glue cup glass support and thickened bracket ensure the table's long service life. Even under heavy-load printing tasks, stable performance can be maintained. This reduces the maintenance and replacement costs of the equipment and improves production efficiency.

The track is made of wear-resistant and scratch-resistant materials with a long service life. The frequency of equipment maintenance and replacement and production costs are reduced. This is an essential consideration for textile companies that have used it for a long time.

3. Convenient operation

The adjustable foot cup adapts to uneven ground, and the table height suits most people's operating habits. This makes the operator more comfortable and convenient and improves work efficiency. It reduces operator fatigue and errors and improves production quality.

The multifunctional positioning code is compatible with machine and manual positioning, and the operation is simple and flexible. Whether it is large-scale production or minor batch customization, it can be easily handled. This provides enterprises with more production options and improves production flexibility.

4. Safe and reliable

The national standard busbar power supply is safe, reliable, and durable. It reduces the risk of electrical accidents and provides a stable power guarantee for your production. This is essential to ensure the continuity and safety of production.

5. Customized service

We offer custom sizes and selections of silk screen printing tables to meet your unique screen printing needs. Whether it is a unique textile size or a specific printing requirement, we can provide you with a suitable solution. This provides companies with more personalized choices and improves the competitiveness of their products.

Here are some application cases of our screen printing table in the textile industry:

1. Garment printing

In garment printing, our screen printing table can achieve high-precision pattern printing, adding unique design and style to clothing whether it is T-shirts, shirts, or jeans, high-quality printing effects can be achieved through our table.

Customizable table size and selection enable our table to adapt to the printing needs of clothing of different styles and sizes. At the same time, the multifunctional positioning code and optimized track design improve printing efficiency and quality.

2. Ribbon printing

Our screen printing platen can provide stable support and precise printing for ribbon printing. Whether it is a narrow or wide ribbon, clear pattern printing can be achieved through our platen.

The widened and thickened track design and wear-resistant and scratch-resistant materials ensure the stable operation of the machine during the ribbon printing process. At the same time, the adjustable foot cup and table height are suitable for most people's operating habits and improve the convenience of operation.

3. Luggage printing

In the field of luggage printing, our screen printing platen can provide high-quality pattern printing for luggage, increasing luggage's beauty and adding value. Whether it is a handbag, backpack, or suitcase, a unique design can be achieved through our platen.

Customized table size and selection enable our platen to adapt to the printing needs of luggage of different sizes and shapes. At the same time, the durable bracket and stable track design ensure the stability and reliability of the printing process.

4. Other Textile Printing

Our screen printing pallets are also widely used in shoe printing, sock printing, transfer film printing, trademark printing, scarf printing, glove printing, elastic band printing, etc. Whatever your textile printing needs are, we can provide you with the right solution.

Our screen printing table is a high-performance equipment designed specifically for the textile industry, with customized sizes, multiple tabletop options, advanced design and technology, excellent product advantages, and a wide range of applications. Come and consult.

Here, you can submit your questions and needs online, we will contact you as soon as possible or direct online reply!

If a response is urgently needed, please call 00864009969505

WeChat

WeChat