Exploring the Best Automatic Screen Printing Machines.

When you think about printing, what comes to mind? For me, it's the vivid colors, intricate designs, and high-quality fabrics. One of the primary methods for creating such appealing products is screen printing, which involves pressing ink through a stenciled mesh screen to create a print design.

While technically a process, screen printing produces end-products that are nothing short of art.

If you're reading this, chances are you're:

A. Already involved in screen printing

B. Considering upgrading from manual to automatic printing

Congratulations on choosing efficiency reduced labor costs, and faster production times if you fall into the second category. Studies indicate that the textile printing machine market will reach $13,988 million by 2025, presenting vast opportunities with a production capacity of 2,139 prints per hour through automatic screen printing.

Once you've decided to upgrade, the next step is finding the right machine. To simplify your search, here’s a rundown of the best automatic screen printing machines available:

Contents

Maximize Your Printing Capabilities with the K3 Table Screen Printing Machine

RapidTag LP4 XL – Four-Color Automatic Screen-Printing Machine

Riley Hopkins 360 6 Color 4 Station Press with XYZ Micro Registration

The K3 Table Automatic Screen Printing Machine offers unmatched versatility and precision, designed for modern business needs. It supports up to 48 spot colors and a wide range of print areas.

• Colors: Up to 48 spot colors printing machine

• Print Area: 600mm X 900mm to 1500mm X 5000mm

• Repeatability Accuracy: Less than 0.02MM

• Printing Speed: 360 to 1200 prints per hour

• Durable carbon steel construction

• Stable pulley framework

• Patented four-column design

• Servo double drive technology

• Mechanical and sensor-based positioning

• Digital squeegee control system

Clothing printing and bags printing, shoe uppers printing, scarves printing, socks printing, labels printing, gloves printing, skateboards printing, hats printing

Compatible with fabrics like viscose, cotton, nylon, wool, silk

ROQ excels in customization, accommodating large printing areas with robust performance.

• Colors: 1 to infinite

• Touchscreen: 15” polychromatic touch panel

• Print Area: Ranges from 20″ x 28″ to 35″ x 51′”

• Honey-comb aluminum pallets

• AC electric printheads with individual functions

• Pneumatic high-lift printheads

• Independent print and flood controls

• AC servo-motor indexing and rotation system

• Rear command for double production

• Micro registration screen system with Vernier scale

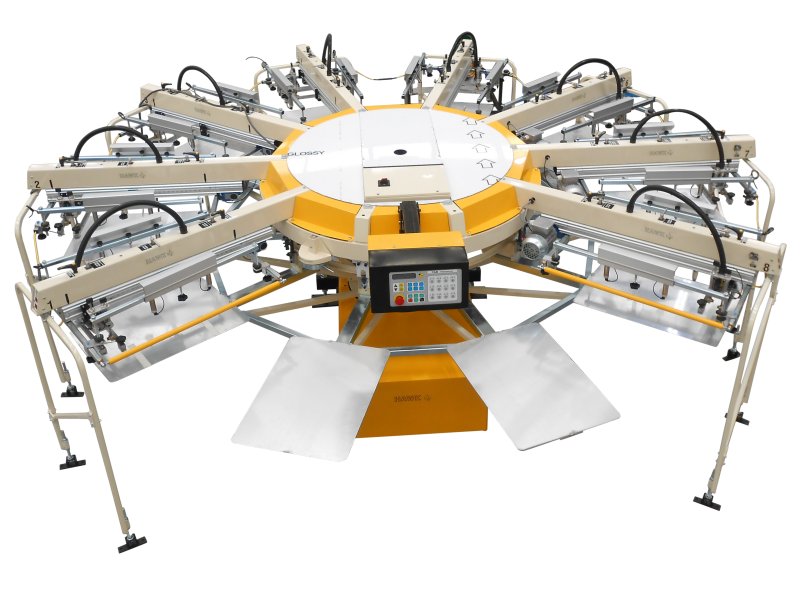

The HAWK HX Series offers a generous print area and is available in multiple colors upon request.

• Colors: Up to 20

• Stations: 22

• Print Area: 20″ x 25″

• Diameter: 6400

• Weight: 5700kg

• Electric indexer and print heads

• Central Off Contact

• Roto Print Program

• Calibrated Individual Off-Contact

• Multi-Functional Foot Switch Pedal

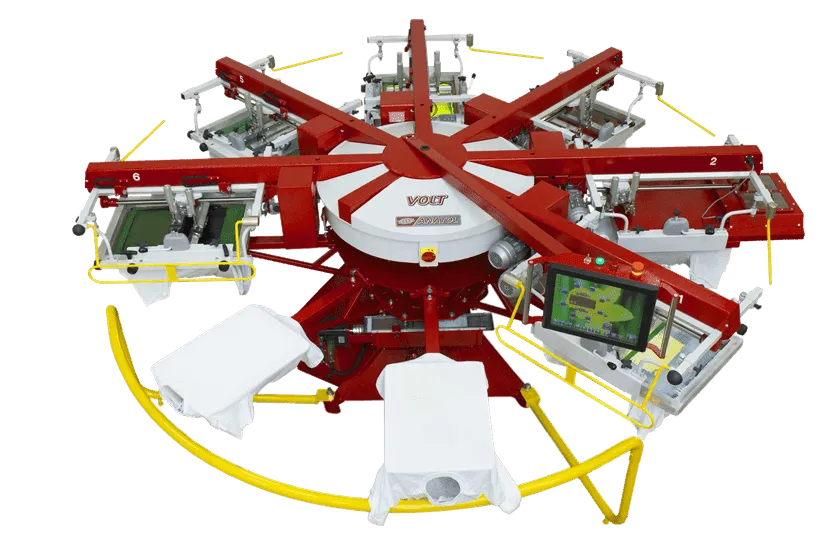

The VOLT by Anatol combines speed, power, and reliability without needing a compressor or chiller.

• Print Area: 15” x 16” to 20” x 28”

• Configurations: 6 stations/2 colors to 20 stations/18 colors

• Touchscreen: 15” with Aries 2 operating system

• Real-time print count and speed display

• Heavy-duty rolled steel frame

• Laser alignment system

• Servo technology

• AC electric print heads

• Safety bars at each print head

An ideal entry-level machine, fully pneumatic for a smooth transition from manual to automatic printing.

• Colors: 6

• Print Area: 15″ x 15″

• Electric: 110V, 50-60Hz, 3amps

• Diameter: 10'

• Intuitive software with functions like Sample Print Mode and Missed Shirt Feature

• Independent print & flood speed

• Super-responsive front & rear micro registration

• Advanced chopper system

• All-access control panel

• Flashback compatible

Quick, easy to maintain, and affordable, this machine delivers consistent results without requiring additional air systems.

• Colors: 8

• Stations: 10

• Power: 120V, 20A or 240V, 20A

• Screen Size: 23″ x 31″

• Platen Size: 16″ x 24

• Dimensions: 144″ x 144″ x 60″

• Weight: 2800lbs

• Direct drive micro registration system

• Independent flood bar and squeegee pressure

• Independent head off-contact adjustment

• Front screen loading

• Hardened steel registration system

• Electric drive and lift

• Electric print heads

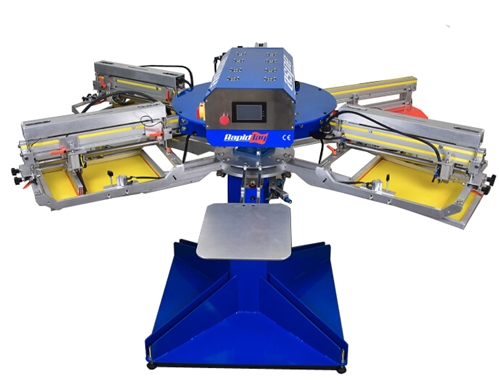

Designed for four-color images, the LP-4XL is ideal for sleeve prints and offers high performance.

• Stations: 6

• Print Heads: 4

• Pallet Size: 13.5″ x 16″

• Frame Size: 16 x 20

• Diameter: 90 inches

• Pneumatic screen lock

• Stroke adjustment

• Squeegee angle adjustment

• Motion sensor

• High-Density Flash Cure Units

• Color Touch Screen

• Hoodie arms

• Servo Indexer

• Adjustable Stroke and flood speed

Stryker's oval design is space-efficient compared to carousel models, optimizing production area usage.

• Print Format Sizes: 24″ x 33″, 27.5″ x 39″, 31.5″ x 43.5″

• Stations: 10 to 52

• Printing Capacity: Up to 132 x 110 cm (52″ x 43.5″)

•Modular design for custom configurations

•Heavy-duty steel construction

•Large touchscreen display with icon-based commands

•Automatic palette preheat mode with temperature sensor

•Adjustable ink retrieval system

•Tool-free front & rear stroke length adjustment

The Cutlass Series balances affordability with performance, making it perfect for everyday use in print shops.

•Colors: 6, 8

•Print Area: 20″ x 20″

•Electric & Air Requirements: Vary by model

•Touchscreen Interface: Simplifies operation

•Air Print Heads & Electric Indexing: Enhance performance

•Advanced Chopper System: Improves stroke length

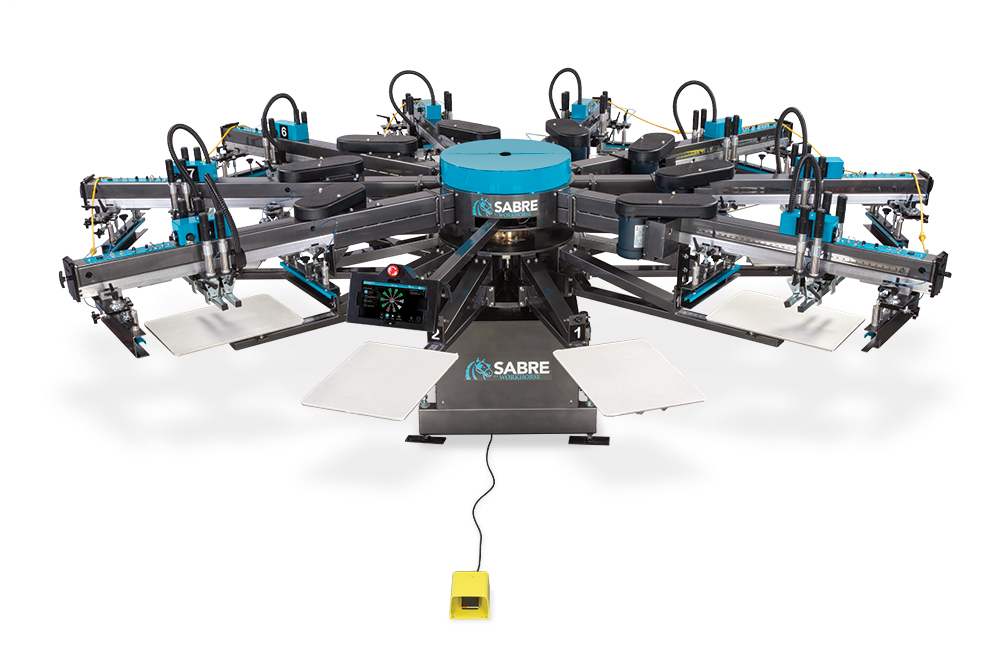

The Sabre is Workhorse’s most feature-rich automatic screen-printing machine.

•Colors: 6-12

•Print Area: 20″ x 20″

•Overall Diameter: Varies by model

•Touchscreen Display: For stroke functions and diagnostics

•Double Indexing: Allows for multiple station indexing

•AC/Electric Printheads: Provide independent control

Specialty: Award-winning design with minimal maintenance.Specifications:

•Colors: 1-18

•Pallet: 12 to 20

•Print Area: 450 x 550 mm to 800 x 1100mm features:

•Aluminum honeycomb pallets, electric squeegee movement

•ndependent control panel, AC servo-motor rotation

•Flash cure placementWarranty: 3 years

- Precision Engineering: Features micro-locking levers, machined tilting blocks, spring-loaded XY micro-adjustments, and a Z micro adjustment for top-tier accuracy.

- Stable Printhead: 4-Point Roller Gates ensure printhead stability and consistent screen placement.

- Customizable Clamps: Choice of side or back clamps to suit various printing needs.

- Adjustable Base: CNC-constructed base with up to 3-inch height adjustment for optimal working height.

Choosing the Best Automatic Screen Printing Machine

Upgrading to an automatic screen printing machine can save time, improve accuracy, and increase production capacity. Consider these factors when choosing:

1. Press Configuration: Match the machine to your print types and design complexities.

2. Size: Ensure it fits your workspace.

3. Power System: Suitability for home or large-scale operations.

4. Support Equipment: Complement with the right dryer, exposure unit, and accessories.

5. Colors and Stations: More options enhance efficiency.

6. Pneumatics: Essential for troubleshooting and maintenance.

7. Compressor Quality: Reliable compressors ensure smooth operations.

By carefully evaluating these factors, you can select an automatic screen printing machine that meets your business needs, ensuring high-quality prints and increased profitability.

Here, you can submit your questions and needs online, we will contact you as soon as possible or direct online reply!

If a response is urgently needed, please call 00864009969505

WeChat

WeChat